Industry 4.0

Industry 4.0 is one of the big buzzwords flying around our ear nowadays. We all wonder about what exactly it is!!!Basically it refers to the 4th industrial revolution where we have seen transformative technologies that have changed the industries. We are now having machines -intelligent Robots connected with smart factories around us.

How did we get here?

First industrial revolution had started in 1770s where we moved from hands to machines, from farms to first factories using steam and water power. Implementing these new technologies were not so easy, it took a long time to go ahead with these technologies. More newer things were happened to iron industry, mining and agriculture. They had soon adopted that.

Second industrial revolution had arrived 100 years later I.e., from 1871 to 1914 where electricity was invented. It has given birth to automation, assembly lines. Increasing electrification has given the kickstart to factories for modern production line. Thus, it is also called as technological revolution.

Third industrial revolution which is also known as digital revolution occurred in 20th century. Arrival of computers happened!! After the end of World War 2, slowdown occurred in industrialization and technological advancements as compared to previous revolutions. Then supercomputer was developed which was playing the most crucial role in development of communication technologies. Machinery began to abrogate the need of human power.

After these there have been huge advancements in technologies. Fourth industrial revolution since its start has combined hardware, software and biology known as the cyber-physical systems. This era is marked by breakthroughs in technologies in fields such as robotics, artificial intelligence, nanotechnology, quantum computing, biotechnology, the internet of things, fifth generation wireless technologies, 3D printing and fully autonomous vehicles.

Some of underlying things of industry 4.0 includes internet of things. We have smart machines and sensors in them that are connected with network and can talk to each other to solve problems. This is what the interconnectivity goals here.

Information transparency afforded by Industry 4.0 technology provides operators with comprehensive information to make decisions.

The Fourth Industrial Revolution consists of many components, including:

• Mobile devices

• Internet of things (IoT) platforms

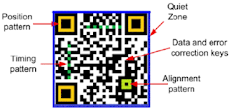

• Location detection technologies (electronic identification)

• Advanced human-machine interfaces

• Authentication and fraud detection

• Smart sensors

• Big data analysis and processes

• Multilevel customer interaction and customer profiling

• Augmented reality/ wearables

• On-demand availability of computer system resources

• Data visualization and triggered "live" training

Mainly these technologies can be summarized into four major components, defining the term “Industry 4.0” or “smart factory”:

• Cyber-physical systems

• Internet of things (IoT)

• On-demand availability of computer system resources

• Cognitive computing

There are so many buzzwords and phrases related to industry 4.0. Some of them are the ones which we have to know and understand definitely to invest in industry 4.0 solutions for business.

• Enterprise Resource Planning (ERP): Business process management tools that can be used to manage information across an organization.

• IoT: IoT stands for Internet of Things, a concept that refers to connections between physical objects like sensors or machines and the Internet.IoT stands for Internet of Things, a concept that refers to connections between physical objects like sensors or machines and the Internet.

• IIoT: IIoT stands for the Industrial Internet of Things, a concept that refers to the connections between people, data, and machines as they relate to manufacturing.IIoT stands for the Industrial Internet of Things, a concept that refers to the connections between people, data, and machines as they relate to manufacturing.

• Big data: Big data refers to large sets of structured or unstructured data that can be compiled, stored, organized, and analyzed to reveal patterns, trends, associations, and opportunities.

• Artificial intelligence (AI): Artificial intelligence is a concept that refers to a computer’s ability to perform tasks and make decisions that would historically require some level of human intelligence.

• M2M: This stands for machine-to-machine, and refers to the communication that happens between two separate machines through wireless or wired networks.

• Digitization: Digitization refers to the process of collecting and converting different types of information into a digital format.

• Smart factory: A smart factory is one that invests in and leverages Industry 4.0 technology, solutions, and approaches.

• Machine learning: Machine learning refers to the ability that computers have to learn and improve on their own through artificial intelligence—without being explicitly told or programmed to do so.

• Cloud computing: Cloud computing refers to the practice of using interconnected remote servers hosted on the Internet to store, manage, and process information.

• Real-time data processing: Real-time data processing refers to the abilities of computer systems and machines to continuously and automatically process data and provide real-time or near-time outputs and insights.

• Ecosystem: An ecosystem, in terms of manufacturing, refers to the potential connectedness of your entire operation—inventory and planning, financials, customer relationships, supply chain management, and manufacturing execution.

• Cyber-physical systems (CPS): Cyber-physical systems, also sometimes known as cyber manufacturing, refers to an Industry 4.0-enabled manufacturing environment that offers real-time data collection, analysis, and transparency across every aspect of a manufacturing operation.

Benefits of Industry 4.0:

Industry 4.0 spans the entire product life cycle and supply chain. It includes more accurate, updated and richer views on production and business processes. Some of the benefits of adopting industry 4.0 for business can be listed as follows:

• It makes you more attractive to the younger workforce.

• It makes your team stronger and more collaborative.

• It allows you to address potential issues before they become big problems.

• It allows you to trim costs, boost profits, and fuel growth.

There are many more things to explore in Industry 4.0 and the way more benefits are there.

Challenges in Implementation of Industry 4.0:

Due to unclarity in business benefits excessive investment is done which ultimately cause high costs. Thus, arising economical challenges.

As automation is happening, there is much decrease in need of human power, which is responsible for job loss of especially blue-collar workers. Also, Privacy concerns, surveillance and distrust, general reluctance to change by stakeholders, threat of redundancy of the corporate IT department such social challenges are also there.

Due to lack of regulation and less importance given to managing standards and forms of certification and unclarity about legal issues and data security there arises political issues.

CREDITS AND REFRENCES :-

- Anjali Nawkar(Team Tech Tuesday)

- https://en.wikipedia.org/wiki/Fourth_Industrial_Revolution

- https://www.epicor.com/en-in/resource-center/articles/what-is-industry-4-0/

- https://youtu.be/yKPrJJSv94M

Comments

Post a Comment